Load Following Power Plant

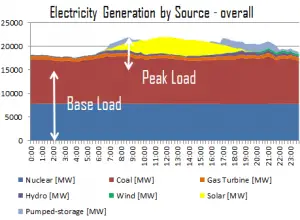

Nuclear power plants may take many hours, if not days, to startup or change their power output. Modern power plants can and do operate as load-following power plants and alter their output to meet varying demands. But baseload operation is the most economical and technically simple mode of operation. It is primarily because they require a long period to heat up the nuclear steam supply system and the turbine-generator to operating temperature. From this point of view, power plant generally is divided into two basic categories:

- Base Load Power Plant

- Load Following Power Plant

Load Following Power Plant

Nuclear power plants (NPPs) have been considered baseload sources of electricity as they rely on technology with low variable costs and high fixed costs. However, that situation is changing in several countries. Today, the main motivation for load following with nuclear power plants comes from the large-scale deployment of intermittent electricity sources (like wind and solar power). An intermittent energy source is any source of energy or electrical power that is not continuously available due to some factor outside direct control. For example, in the absence of an energy storage system, solar does not produce power at night or in bad weather and varies between summer and winter.

On the other hand, electrical energy must be generated at the same rate at which it is consumed. A sophisticated control system is required to ensure that the power generation very closely matches the demand. If the demand for power exceeds supply, the imbalance can cause power plants and transmission equipment to automatically disconnect and/or shut down to prevent damage. This may lead to a cascading series of shutdowns and a major regional blackout in the worst case. The challenge is not only technical. Due to the sudden influx of large amounts of wind power, German, Dutch, Czech, and Austrian power markets have experienced several hours of negative electricity prices in recent years and many more hours with prices that were lower than the variable costs of nuclear power plants, which have the lowest variable costs among the large-scale established power sources. Moreover, the load follows operation is economically very inefficient as nuclear power generation is composed almost entirely of fixed and sunk costs. Therefore, lowering the power output doesn’t significantly reduce generating costs and the plant.

To manage this problem, the utilities have had to implement or improve the maneuverability capabilities of their NPPs to adapt the electricity supply to daily, seasonal, or other variations in power demand. The power plant with this improved maneuverability is known as the load-following power plant. In general, the load-following power plant is a power plant that adjusts its power output as electricity demand fluctuates throughout the day. Load following plants are typically in-between baseload and peaking power plants.

For example, according to the current version of the European Utilities Requirements (EUR), the nuclear power plant must be capable of daily load cycling operation between 50% and 100 % of its rated power, with a rate of change of the electric output of 3-5% of rated power per minute.

From the reactor operation viewpoint, in the case of pressurized water reactors (PWRs), the reactor thermal power and the global power distribution (especially the AFD) are controlled by manipulating several factors which affect the core’s reactivity. In PWRs, these factors are especially:

- position of control rods,

- the concentration of boric acid in the RCS

- core inlet temperature

A control rod is removed from or inserted into the reactor core to increase or decrease the reactor’s reactivity (increase or decrease the thermal power). For example, control rods insertion causes the addition of new absorbing material into the core, and this causes a decrease in thermal power.

Boric acid is used to compensate for an excess of reactivity of reactor core along the fuel burnup (long-term reactivity control) and compensate for the negative reactivity from the power defect and xenon poisoning during power increase to nominal power.

Special attention requires the axial flux difference control. The axial flux difference is defined as the difference in normalized flux signals (AFD) between the top and bottom halves of a two-section excore neutron detector:

Special attention requires the axial flux difference control. The axial flux difference is defined as the difference in normalized flux signals (AFD) between the top and bottom halves of a two-section excore neutron detector:

AFD or ΔI = Itop – Ibottom

The AFD is sensitive to many-core-related parameters such as control bank positions, core power level, axial burnup, axial xenon distribution, and, to a lesser extent, reactor coolant temperature and boron concentrations.

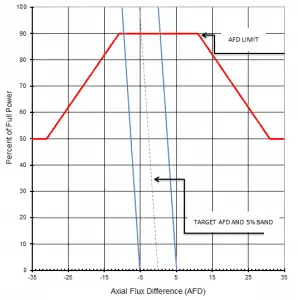

During power maneuvers, the operating scheme used to control the axial power distribution involves maintaining the AFD within a tolerance band around a burnup dependent target, known as the target flux difference, minimizing the variation of the axial peaking factor and axial xenon distribution.

For plants operating with so-called “constant axial offset control – CAOC”, the AFD limit involves a target band. This target band is, for example, +5% and -5% around the target value. Since the xenon concentration and distribution are flux and time-dependent, the longer the core operates outside its target band, the greater the probability of initiating a xenon transient.

Load Follow without Boron Adjustment

Smaller load changes do not require boron adjustment. For a power decrease, without using boron addition to overcome the positive reactivity added by the power defect, the control rods must be inserted to maintain Tavg. From this point on, with a continuing decrease in power, the pressure inside the steam generator will increase, adding negative reactivity.

Smaller load changes do not require boron adjustment. For a power decrease, without using boron addition to overcome the positive reactivity added by the power defect, the control rods must be inserted to maintain Tavg. From this point on, with a continuing decrease in power, the pressure inside the steam generator will increase, adding negative reactivity.

Load Follow with Boron Adjustment

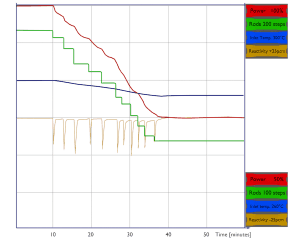

More extensive maneuvers usually require boron adjustment to compensate for xenon reactivity changes, thereby keeping the control rods within their axial flux distribution (AFD) target band. Boron concentration changes during plant operation are required whenever axial flux difference (AFD) extends outside the allowable target band. As was written, this target band is, for example, +5% and -5% around the target value. Following the power level change made by the control rods, the plant operator or the control system makes boron concentration adjustments whenever the AFD approaches the limits of the target band.

Grey control rods

Some nuclear power plants use so-called “grey control rods” for load following. These plants can make power maneuvering between 30% and 100% of rated power, with a slope up to 5% of rated power per minute. They can respond very quickly to the grid requirements. Special control rods have to be used to fulfill these requirements without introducing a large perturbation of the power distribution. These control rods are called “grey” control rods. Grey control rods use a grey neutron absorber, which absorbs less neutrons than a “black” absorber. Consequently, they cause smaller depressions in the neutron flux and power in the vicinity of the rod. The rod control system automatically modulates the insertion of the axial offset (grey) control bank, which controls the axial power distribution.

In the case of the boiling water reactors (BWRs), the power regulation is performed by changing the coolant flow rate (using the recirculation pumps) and/or the control rods. No boron regulation is used in BWRs.