Strengthening of Metals

The strength of metals and alloys can be modified through various combinations of cold working, alloying, and heat treating. As discussed in the previous section, the ability of a crystalline material to deform largely plastically depends on the ability for dislocation to move within a material. Therefore, impeding the movement of dislocations will result in the strengthening of the material. For example, a microstructure with finer grains typically results in higher strength and superior toughness than the same alloy with physically larger grains. In the case of grain size, there may also be a tradeoff between strength and creep characteristics. Other strengthening mechanisms are achieved at the expense of lower ductility and toughness. There are many strengthening mechanisms, which include:

- Solid Solution Strengthening (alloying)

- Work Hardening (Cold Working)

- Precipitation Hardening

- Grain Refinement

- Transformation Hardening

Work Hardening – Cold Working

Strain hardening, also called work-hardening or cold-working, is a strengthening method often used in materials whose strength cannot be increased by heat treatment, e.g., by changes in their phase composition. Work hardening may be desirable, undesirable, or inconsequential, depending on the context. It is called cold-working because plastic deformation must occur at a temperature low enough that atoms cannot rearrange themselves. The simplest way of cold- working is beating a red-hot piece of metal on an anvil. Cold-working is a process of making a metal harder and stronger through plastic deformation. When a metal is plastically deformed, dislocations move, generating additional dislocations. Dislocations can move if the atoms from one of the surrounding planes break their bonds and rebond with the atoms at the terminating edge. The dislocation density in a metal increases with deformation or cold work because of dislocation multiplication or the formation of new dislocations. The more dislocations within a material, the more they interact and become pinned or tangled. This will result in a decrease in the mobility of the dislocations and a strengthening of the material. Cold working involves the reduction in the thickness of a material. Plate and sheets of different thicknesses are produced by cold rolling. Wire and tubes of different diameters and wall thicknesses are produced by drawing. All aluminum alloys can be strengthened by cold working.

Strain hardening, also called work-hardening or cold-working, is a strengthening method often used in materials whose strength cannot be increased by heat treatment, e.g., by changes in their phase composition. Work hardening may be desirable, undesirable, or inconsequential, depending on the context. It is called cold-working because plastic deformation must occur at a temperature low enough that atoms cannot rearrange themselves. The simplest way of cold- working is beating a red-hot piece of metal on an anvil. Cold-working is a process of making a metal harder and stronger through plastic deformation. When a metal is plastically deformed, dislocations move, generating additional dislocations. Dislocations can move if the atoms from one of the surrounding planes break their bonds and rebond with the atoms at the terminating edge. The dislocation density in a metal increases with deformation or cold work because of dislocation multiplication or the formation of new dislocations. The more dislocations within a material, the more they interact and become pinned or tangled. This will result in a decrease in the mobility of the dislocations and a strengthening of the material. Cold working involves the reduction in the thickness of a material. Plate and sheets of different thicknesses are produced by cold rolling. Wire and tubes of different diameters and wall thicknesses are produced by drawing. All aluminum alloys can be strengthened by cold working.

Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium. However, others can only be strengthened via work hardenings, such as pure copper and aluminum.

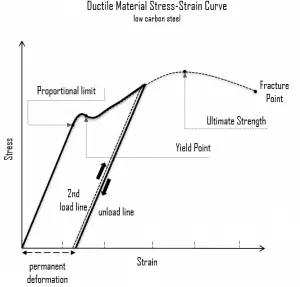

Strain hardening is one of the stages in the stress-strain curve in the strain hardening region. This region starts as the strain goes beyond the yield point and ends at the ultimate strength point, the maximal stress shown in the stress-strain curve. In this region, the stress mainly increases as the material elongates, except that there is a nearly flat region at the beginning.