As for the Carnot cycle, the thermal efficiency tends to increase as the average temperature at which energy is added by heat transfer increases. This is the common feature of all thermodynamic cycles.

One of the possible ways is to superheat and reheat the working steam. Both processes are very similar in their manner:

- Superheater – increases the steam temperature above the saturation temperature

- Reheater – removes the moisture and increases steam temperature after a partial expansion.

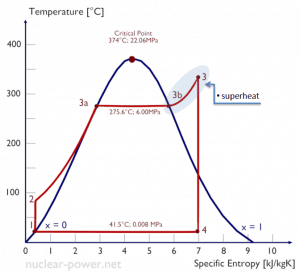

The superheating process is the only way to increase the peak temperature of the Rankine cycle (and to increase efficiency) without increasing the boiler pressure. This requires another type of heat exchanger called a superheater, which produces superheated steam.

Superheated vapor or superheated steam is a vapor at a temperature higher than its boiling point at the absolute pressure where the temperature is measured.

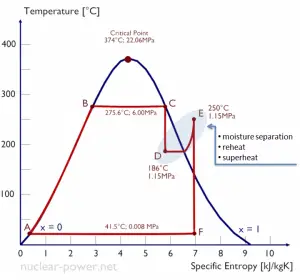

Reheat allows delivering more of the heat at a temperature close to the peak of the cycle. This requires the addition of another type of heat exchanger called a reheater. The use of the reheater involves splitting the turbine, i.e., using a multi-stage turbine with a reheater. It was observed that more than two reheating stages are unnecessary since the next stage increases the cycle efficiency only half as much as the preceding stage.

The turbine’s high and low-pressure stages are usually on the same shaft to drive a common generator, but they have separate cases. After a partial expansion (point D), the flow is extracted with a reheater, run back through the heat exchanger to heat it back up to the peak temperature (point E), and then passed to the low-pressure turbine. The expansion is then completed in the low-pressure turbine from point E to point F.

In the superheater, further heating at fixed pressure results in increases in both temperature and specific volume. The process of superheating water vapor in the T-s diagram is provided in the figure between state E and the saturation vapor curve. As can also be seen, wet steam turbines (e.g.,, used in nuclear power plants) use superheated steam, especially at the inlet of low-pressure stages. Typically most nuclear power plants operate multi-stage condensing wet steam turbines (the high-pressure stage runs on saturated steam). In these turbines, the high-pressure stage receives steam (this steam is nearly saturated steam – x = 0.995 – point C at the figure) from a steam generator and exhausts it to a moisture separator-reheater (point D). The steam must be reheated or superheated to avoid damages caused to the blades of the steam turbine by low-quality steam. The high content of water droplets can cause rapid impingement and erosion of the blades, which occurs when condensed water is blasted onto the blades. To prevent this, condensate drains are installed in the steam piping leading to the turbine. The reheater heats the steam (point D), and then the steam is directed to the low-pressure stage of the steam turbine, where it expands (point E to F). The exhausted steam is at a pressure well below atmospheric, and, as can be seen from the picture, the steam is in a partially condensed state (point F), typically of a quality near 90%. Still, it is much higher vapor quality than that it would be without reheat. Accordingly, superheating also tends to alleviate the problem of low vapor quality at the turbine exhaust.

Since the temperature of the primary coolant is limited by the pressure inside the reactor, superheaters (except a moisture separator reheater) are not used in nuclear power plants, and they usually operate a single wet steam turbine.