Classification of Turbines – steam supply and exhaust conditions

Steam turbines may be classified into different categories depending on their purpose and working pressures. The industrial usage of a turbine influences the initial and final conditions of steam. A pressure difference must exist between the steam supply and the exhaust for any steam turbine to operate.

This classification includes:

- Condensing Steam Turbine,

- Back-pressure Steam Turbine,

- Reheat Steam Turbine,

- Turbine with Steam Extraction

Extraction Turbine – Turbine with Steam Extraction

Extraction-type turbines are common in all applications. In some applications, when required, steam can be extracted from the turbine before steam flows through the last stage, named extraction turbine. As in back-pressure turbines, extracted steam can be used for many industrial processes, or it can be used to improve the efficiency of the thermodynamic cycle. The second case is usually known as heat regeneration.

Almost all large steam turbines use heat regeneration (i.e., they are extraction turbines) since it reduces the amount of fuel that must be added in the boiler. The reduction in the heat added can be made by transferring heat (partially expanded steam) from certain sections of the steam turbine, which is normally well above the ambient temperature, to the feedwater. Note that most of the energy contained in the steam is in the form of latent heat of vaporization. Extraction flows may be controlled with a valve or left uncontrolled.

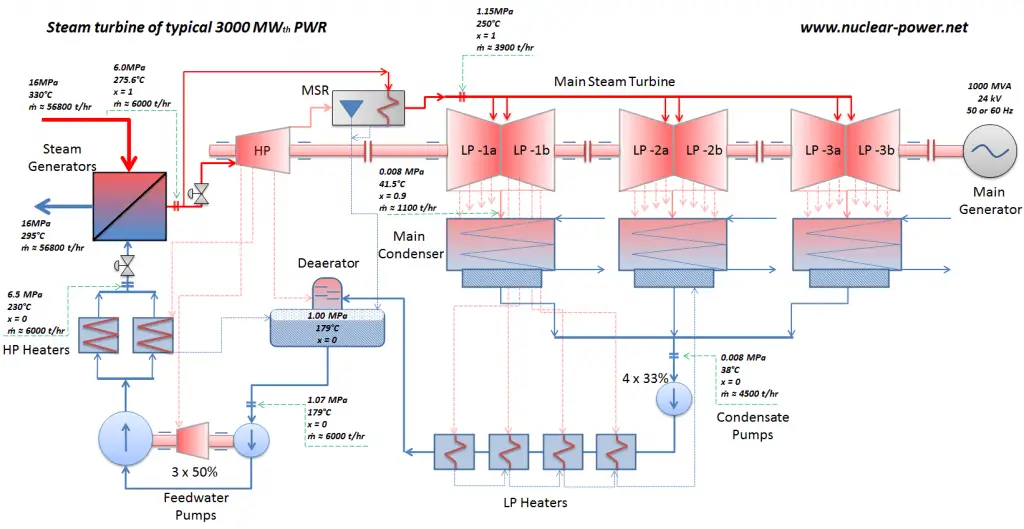

For example, most nuclear power plants operate a single-shaft turbine-generator that consists of one multi-stage HP turbine with 3 or 4 self-regulating extraction lines and three parallel multi-stage LP turbines with 3 or 4 self-regulating extraction lines.

The high-pressure feedwater heaters are usually heated by extraction steam from the high-pressure turbine, HP, whereas the low-pressure feedwater heaters are usually heated by extraction steam from the low-pressure turbine, LP. Both are usually self-regulating. It means that the greater the flow of feedwater, the greater the rate of heat absorption from the steam and the greater the flow of extraction steam.