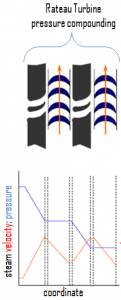

Pressure Compounding – Rateau Turbine – Zoelly Turbine

A pressure-compounded impulse stage is a row of fixed nozzles followed by a row of moving blades, with multiple stages for compounding. In this type, the total pressure drop of the steam does not take place in the first nozzle ring but is divided up between all the nozzle rings. The effect of absorbing the pressure drop in stages is to reduce the velocity of the steam entering the moving blades. The steam from the boiler is passed through the first nozzle ring in which is only partially expanded. It then passes over the first moving blade ring, where nearly all of its velocity (momentum) is absorbed. From this ring, it exhausts into the next nozzle ring and is again partially expanded. This method of pressure compounding is used in Rateau and Zoelly turbines, but such turbines are bigger and bulkier in size.